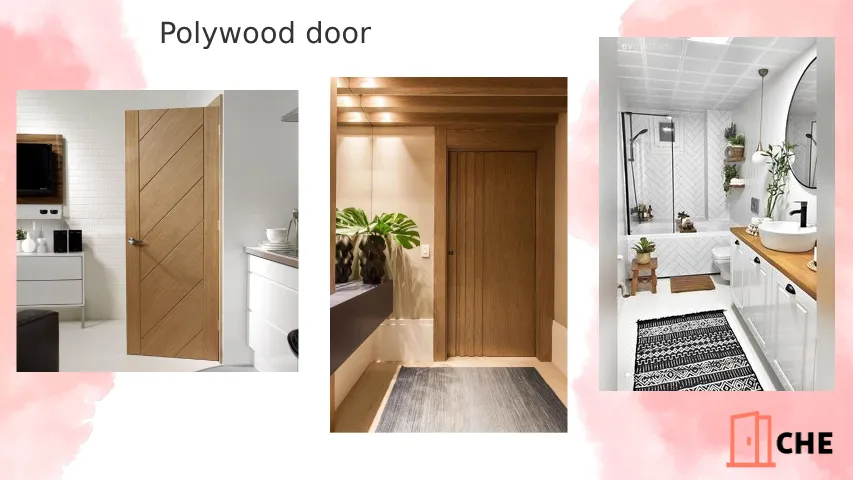

Polywood door is known as a class of waterproof doors. Due to their different interior structures, Polywood doors are more expensive than other kinds of doors. A combination of wood particles and polymer is used in its interior structure. The polymer makes the door waterproof. That’s why Polywood doors are best known for being used in bathrooms and toilets.

What are the advantages and characteristics of Polywood doors?

- Anti-bacterial and anti-fungal: Because the wood is completely dehumidified during the whole procedure of manufacturing a Polywood door, there is no room for bacteria and their growth on any surface of the door.

- Waterproof: Since they have a different and particular structure, Polywood doors are the best waterproof doors you can find in the market.

- Impact strength and scratch resistance: Being impact resistant makes Polywood doors distinct from and more attractive than other waterproof doors such as ‘ABS’ doors. Resin and PVC used in its foundation have made this waterproof door resistant to high force, shock, and scratches.

- Fire resistance: Another significant tip in its foundation is the material used which prevents the flames from burning the wood. This issue is very noticeable in reducing the combustion time.

- Eco-friendly: The door is made of polymer and wood particles so that it wards off deforestation activities by not cutting up more trees for door manufacturing goals hence this saves the forests.

- Easy to clean: Polywood doors do not need renovating and mending regularly because of dust, force, shock, stain, etc. They are easy to clean and keep fresh by using gentle detergents.

- Long lasting: Polywood material is originally made from HPDE – which stands for “High-Density Polyethylene” – a durable plastic. This plastic material is useful because it does not attract termites and other pests. Made of a combination of resistant plastic and wood, Polywood doors enjoy resistance against shocks, scratches, and temperature changes. This characteristic – in the long run – keeps the door’s shape and appearance as fresh as it was the first day.

Factors affecting the price of Polywood doors

The door and frame of Polywood cost less than Russian wood and MDF. This does not indicate a lower quality of the material, but the price differs due to the different structures of Polywood doors. It’s not the case of a price-quality relationship.

Another significant fact about the price is the uniqueness of the foundation in the Plywood door structure. Compared to other kinds of waterproof doors, the structure provides you with the same price range and it doesn’t lead to an increased price.

What about the size?

Wood and polymer-made doors are manufactured in standard sizes as well as other doors. The sizes are regulated according to international standards to use them by the space available.

- Standard Width of the door: 210 – 240 cm

- Standard Height of the door: 70 – 100 cm

- Standard Breadth of the door: 16 cm

Some important tips when you decide to buy Polywood doors

It is important to take into account some tips before you decide to purchase Plywood doors. Some tips are suggested below:

- Material quality: Be sure about the good quality of wood and plastic used in the door foundation. Polywood doors, thanks to their structure and material, are highly resistant to humidity and temperature changes. On the other hand, these doors are manufactured with advanced technologies and high-tech.

- Appearance and design: It is very important to pay attention to your desire and style of inner architecture when choosing a door’s form and color. The design of the door should suit the place in which it is going to be installed so that it can add charm to your residential and business place.

- Vocal remover and temperature isolator: You should choose a door that filters noise and saves heat. This is to avoid waste of energy in cold seasons like winter as well as to keep a calm and cozy bedroom, study room, workplace, etc. by not letting the extra noises in.

- Humidity and scratch resistance: The door you buy must be resistant to water and scratches.

Ordering Polywood doors

- It will take 14 – 21 working days to prepare a Polywood door.

- The price differs according to the size of the door and frame.

- This product is widely used in hospitals, toilets, and bathrooms. So if you are ordering for these purposes, do not doubt and order now.

Source: polywood.org